You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My new babies ...

- Thread starter Paul B

- Start date

EQnoble

Well-known member

Nice compound, I need a new one so if you could let me know how that one goes and if good the model number I would appreciate it.

I bought a table saw about 6 months ago and even though it is just shy of 15 amps it still isn't enough...think I need to go old school though as I have yet to find a new table saw that can hang.

This is my newest black and yellow tool and actually the last tool that I have purchased altogether.

At the moment I am breaking for the winter since my stock is kept at a non-optimal temperature and since I can't afford an indoor workshop but my latest project has been to make my own 1.5 inch panel stock by doing glue ups of some choice hardwood scraps cut to shapes that when assembled create optical illusions or geometric patterns that create the illusion of depth, something like this.

What is your next project you have coming out of the woodwork?

I bought a table saw about 6 months ago and even though it is just shy of 15 amps it still isn't enough...think I need to go old school though as I have yet to find a new table saw that can hang.

This is my newest black and yellow tool and actually the last tool that I have purchased altogether.

At the moment I am breaking for the winter since my stock is kept at a non-optimal temperature and since I can't afford an indoor workshop but my latest project has been to make my own 1.5 inch panel stock by doing glue ups of some choice hardwood scraps cut to shapes that when assembled create optical illusions or geometric patterns that create the illusion of depth, something like this.

What is your next project you have coming out of the woodwork?

That's a nice bit of marquetry.

I haven't squared the saw up yet so likely won't be using it until next week.

I'm expecting good things though - it's a DeWalt 780 (minus the blade LED) http://www.dewalt.com/en-us/product...uble-bevel--sliding-compound-miter-saw/dws780

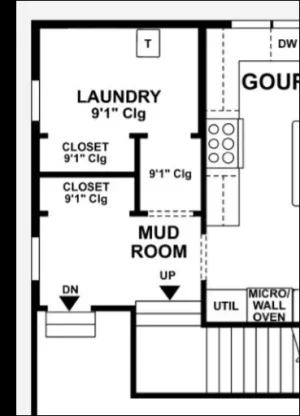

I have a few things planned for our new house (which we move in to in August) but the first thing is a mud room drop zone.

I don't have a complete 3D render but this should give a good idea of what it's going to be.

I'm going to use it for shaker style cabinetry (doors), as well as general hardwood edging.

I haven't squared the saw up yet so likely won't be using it until next week.

I'm expecting good things though - it's a DeWalt 780 (minus the blade LED) http://www.dewalt.com/en-us/product...uble-bevel--sliding-compound-miter-saw/dws780

I have a few things planned for our new house (which we move in to in August) but the first thing is a mud room drop zone.

I don't have a complete 3D render but this should give a good idea of what it's going to be.

It's a Freud tongue and groove matched set: http://www.freudtools.com/index.php/products/product/99-036are those raised panel bits on top of the router's hard shell case?

I'm going to use it for shaker style cabinetry (doors), as well as general hardwood edging.

rainmotorsports

Well-known member

I am a furniture installer so I wont say I am into wood working but our works goes way beyond basic power tools sometimes. Should serve you pretty well but I would have gotten an impact set with the drill. I don't know how we ever survived without impacts. I was doing 3 inch screws through wall mounts into dry wall that is plywood backed. If you don't feather the drill the bit will cam out like crazy. I switched to the impact and just started shooting them in like crazy.

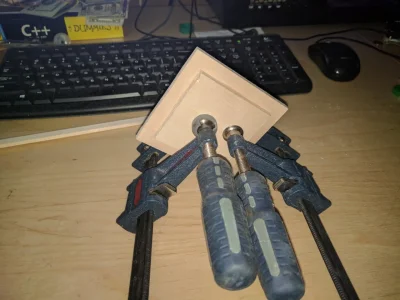

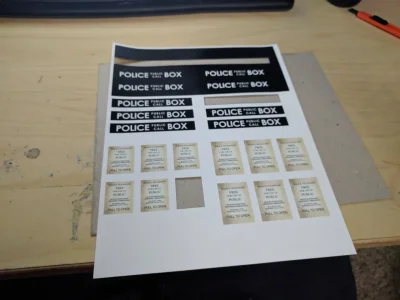

However I recently started building a tardis ring box for my soon to be fiance:

From:

Mostly used a chisel and sand paper.

However I recently started building a tardis ring box for my soon to be fiance:

From:

Mostly used a chisel and sand paper.

Attachments

-

IMG_20170128_195706.webp113.6 KB · Views: 91

IMG_20170128_195706.webp113.6 KB · Views: 91 -

IMG_20170128_210046.webp62.5 KB · Views: 83

IMG_20170128_210046.webp62.5 KB · Views: 83 -

IMG_20170128_233053.webp74.5 KB · Views: 84

IMG_20170128_233053.webp74.5 KB · Views: 84 -

IMG_20170129_011435.webp64.2 KB · Views: 83

IMG_20170129_011435.webp64.2 KB · Views: 83 -

IMG_20170130_234717.webp78.6 KB · Views: 86

IMG_20170130_234717.webp78.6 KB · Views: 86 -

IMG_20170202_223229.webp86.8 KB · Views: 83

IMG_20170202_223229.webp86.8 KB · Views: 83 -

IMG_20170206_145508.webp75.7 KB · Views: 85

IMG_20170206_145508.webp75.7 KB · Views: 85 -

IMG_20170206_201722.webp133.8 KB · Views: 87

IMG_20170206_201722.webp133.8 KB · Views: 87 -

IMG_20170207_204038.webp89 KB · Views: 85

IMG_20170207_204038.webp89 KB · Views: 85 -

IMG_20170207_204829.webp65.9 KB · Views: 83

IMG_20170207_204829.webp65.9 KB · Views: 83 -

IMG_20170207_212347.webp101.8 KB · Views: 87

IMG_20170207_212347.webp101.8 KB · Views: 87

I considered an impact driver but it's no good for the majority of the work I plan to do.

For cabinetry it will just rip through the faces.

I'll regret it when I extend the deck next year though ...

Having said that, until now I've strictly been hand tools only - try installing a 200 square foot deck with a hand saw and manual screwdriver and you'll know you've done a good day's work

I bit of hard work never hurt anyone

For cabinetry it will just rip through the faces.

I'll regret it when I extend the deck next year though ...

Having said that, until now I've strictly been hand tools only - try installing a 200 square foot deck with a hand saw and manual screwdriver and you'll know you've done a good day's work

I bit of hard work never hurt anyone

EQnoble

Well-known member

Technically not marquetry (though I find that to be a fun challenge) as the glued up piece are just shy of 2 inches thick and once solid they head through the planer to bring them to a 1.5" dimension and then panels are final assembled from three or four 8 foot long glued up board sections and then hand planed and sanded to finish.That's a nice bit of marquetry.

This image kind of explains what I am doing with custom jig building to do this stock creation task, just imagine the glue up stock is 2" thick and will be glued up into 1 foot wide sections up to 8 feet long with logical start/stop points for seamless tile assembling.

To assemble the one foot sections (since I don't have a 40" capacity through-feed planer) I would use a full length glued up joint of some variety and clamp them together and then jig up a router with a solid carbide bit to clean up the face and mill out the imperfections near near the joint if any with a jig similar to this image followed by some finish sanding.

Finished panels (12) will be made to suit (3'x8' & 3'x4') for a large desk/office project I am doing for my home and veneer finishes don't hold up well comparatively nor as you know do they play well with a sanding and refinishing down the road.

You give me a good idea with that mention of marquetry however as it may be nice to mimic the panel patterns in creating some desktop organizers and whatever other doodads a desk has using such a technique which I hadn't thought of. It certainly would be easier with the smaller stuff rather than making smaller dimension custom panel stock.

I have actually heard good things about that one actually, she's a beaut.I haven't squared the saw up yet so likely won't be using it until next week.

I'm expecting good things though - it's a DeWalt 780 (minus the blade LED) http://www.dewalt.com/en-us/product...uble-bevel--sliding-compound-miter-saw/dws780

Diablo blades for finish work in a trued up chop saw do some really nice work FTR. I would also invest (if you have not already) in a really high quality straight carbide bit if you are open to suggestions (whoever your favorite toolmaker is).

A solid carbide straight bit will be a work horse making lots of cuts and under heat the carbide holds up it's edge and retains it's hardness and when you combine that with high speed cutting you end up with a much better surface finish quality and reducing the amount of sanding required on any project is ALWAYS good in my book.

Lots of potential in there wish I could see the room you are applying it to, sort of before -> sketch -> after.I have a few things planned for our new house (which we move in to in August) but the fist thing is a mud room drop zone.

I don't have a complete 3D render but this should give a good idea of what it's going to be.

View attachment 147935

View attachment 147936

View attachment 147939

View attachment 147938

View attachment 147937

Same principle as a raised panel set except it has the advantage of being more versatile and universal whereas a raised panel set will pretty much only ever be a raised panel set.It's a Freud tongue and groove matched set: http://www.freudtools.com/index.php/products/product/99-036

I'm going to use it for shaker style cabinetry (doors), as well as general general hardwood edging.

I am going to say I find an impact wrench a great tool for custom clamp jig building. Using bolts for the final pressure application is a nice way to do it if you have this tool and they are great for a many other things (I am going to add a photo to the media gallery soon that shows an application of this tool). Washer stacks are your friend.I considered an impact driver but it's no good for the majority of the work I plan to do.

For cabinetry it will just rip through the faces.

I'll regret it when I extend the deck next year though ...

Having said that, until now I've strictly been hand tools only - try installing a 200 square foot deck with a hand saw and manual screwdriver and you'll know you've done a good day's work

A bit of hard work never hurt anyone

Hand building a deck...I'm out. Sawing is not bad once in a while, but I don't use a screwdriver for almost anything other than as row divider, a paint can opener, or to fasten cabinet hardware

rainmotorsports

Well-known member

Oh and what the hell is it with imperial measurements only in the US?

I wish I'd shipped all of my tools over now - it's a pain having to work in feet and inches.

Get with the times!

In your line of work I am not sure how badly it will effect you. Drill bits can be had in MM but unlike metric driving buts, those are really hard to get here. I work on a lot of metric furniture and it sucks to have to size up a hole to replace dowels etc. You can measure however you want. But a lot of your household items will be imperial and you might just want to go with it.

I've done some marquetry (a long time ago) - it's time consuming and painstaking but very rewarding.u give me a good idea with that mention of marquetry however

As is French polishing, if you've ever done that.

Yes, I've got some top notch straight bits - I'm going to be using my router table for edge planing/jointing (amongst other things) as I don't have a planer.I would also invest (if you have not already) in a really high quality straight carbide bit

I'm very much of the opinion that you pay 2 to 3 times what you want for tools but you only need to pay once and it results in a far superior finish.

It's actually a closet as standard but I've asked the builder to leave it as a plain alcove without the wings/stubs, doors, etc.Lots of potential in there wish I could see the room you are applying it to, sort of before -> sketch -> after.

For context:

The steps down at the bottom left are to the garage (the plan is the reverse of the photos).

I'm a bit of a masochist - I'll usually always opt for the hard/physical optionHand building a deck...I'm out.

Like lugging a 65lb saw to the car rather than using a cart ...

Tell me about it - I only get it in my hands and wrists but I expect it's just a matter of time at my age.Tell the bit about the hard work to my arthritis.

I can work with either but I far prefer metric - working in base 10 in increments of 1 mm is far simpler (and accurate) than using eighths or sixteenths of an inch.In your line of work I am not sure how badly it will effect you. Drill bits can be had in MM but unlike metric driving buts, those are really hard to get here. I work on a lot of metric furniture and it sucks to have to size up a hole to replace dowels etc. You can measure however you want. But a lot of your household items will be imperial and you might just want to go with it.

rainmotorsports

Well-known member

I can work with either but I far prefer metric - working in base 10 in increments of 1 mm is far simpler (and accurate) than using eighths or sixteenths of an inch.

My good sir you have forgotten about 32nds of an inch:

It's as old as it looks by the way. I inherited a lot of Craftsmen tools as well from the Sears and Roebuck era and despite having newer tools I do use them.

EQnoble

Well-known member

Indeed, but with some determination some nice results can be achieved. I don't think what I do is considered a French polish or English polish though the principle is very similar and I would guess equally demanding. Basically layers of cover alternating with progressively higher grit abrasion until I get to the point that I am basically wet sanding for a mirror.I've done some marquetry (a long time ago) - it's time consuming and painstaking but very rewarding.

As is French polishing, if you've ever done that.

I could not agree with this any stronger than I do already.I'm very much of the opinion that you pay 2 to 3 times what you want for tools but you only need to pay once and it results in a far superior finish.

Ahhh perspective..nice, I can't wait to see what you come up with.It's actually a closet as standard but I've asked the builder to leave it as a plain alcove without the wings/stubs, doors, etc.

View attachment 147955 View attachment 147956 View attachment 147957

For context:

View attachment 147958

The steps down at the bottom left are to the garage (the plan is the reverse of the photos).

You may or may not be a sick sick person. My vote will reach finality if your palm nailer benefits from hand lotion.I'm a bit of a masochist - I'll usually always opt for the hard/physical option

Like lugging a 65lb saw to the car rather than using a cart ...

Mine isn't from anything as prestigious, I am sure 90% of it is martial arts training specifically all those childhood years spent thinking that a a ninja would naturally be a suitable and available occupation in the future.Tell me about it - I only get it in my hands and wrists but I expect it's just a matter of time at my age.

It's as old as it looks by the way. I inherited a lot of Craftsmen tools as well from the Sears and Roebuck era and despite having newer tools I do use them.

If I had an old cast iron based saw with door access to the motor (and the indoor space to house and use it) I would be one smug dude.

whynot

Well-known member

They would cost a lot more!I thought it was to have twin children.

teletubbi

Well-known member

I prefer https://www.festool.de for the tools I need to make my money with woodworking.

For metalworking there are others better. For drilling a third company comes in.

Has nothing to do that I am German.

For metalworking there are others better. For drilling a third company comes in.

Has nothing to do that I am German.

Jaxel

Well-known member

I used to make arcade sticks: http://www.joystickvault.com/showgallery.php?cat=500&ppuser=235

Similar threads

- Question

- Replies

- 25

- Views

- 1K

- Question

- Replies

- 1

- Views

- 240

- Replies

- 3

- Views

- 1K

- Replies

- 2

- Views

- 85

- Question

- Replies

- 10

- Views

- 1K